Taiwan Professional Metal Processing and Manufacturing Services

FKX possesses profound technical expertise in metal processing, specializing in a diverse range of metal processing services including metal nameplate production, electroforming nameplates, etched panels, and die-cast signs. Utilizing advanced metal processing equipment and sophisticated craftsmanship, we provide high-quality metal signage solutions to industries such as manufacturing, automotive, home appliances, and electronics in Taiwan.

Metal Nameplates: The Professional Choice for Durable Quality

Metal nameplate manufacturing is one of our core services, primarily including stainless steel, aluminum, iron, and copper nameplates. These products are widely used in various industrial equipment, machinery markings, and corporate branding displays.

- Features of stainless steel nameplates:

useSUS304Made of high-grade stainless steel, our nameplates possess excellent corrosion resistance, high-temperature resistance, and mechanical strength. Our stainless steel nameplate manufacturing process includes multiple steps such as laser cutting, precision stamping, surface polishing, and screen printing to ensure a beautiful appearance and clear lettering.Service life of over 10 yearsIt is particularly suitable for use in harsh environments such as marine environments, chemical equipment, and food machinery. - Aluminum nameplate production:

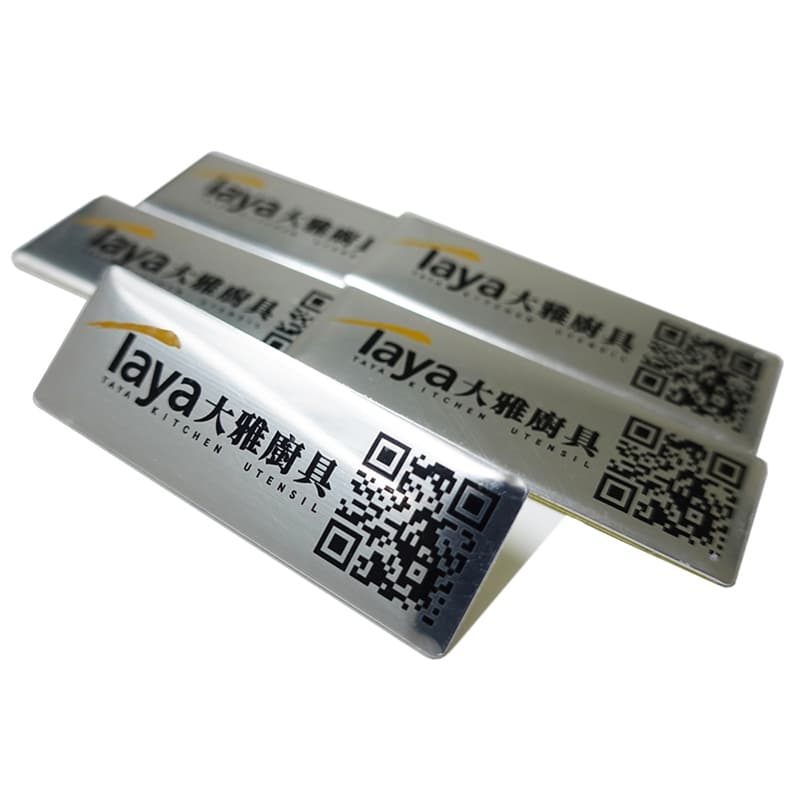

Made from high-purity aluminum alloy and anodized, these nameplates boast high surface hardness and excellent wear resistance. Lightweight, with excellent thermal conductivity and a stylish appearance, they are widely used in high-tech industries such as electronics, 3C devices, and precision instruments. We offer a variety of surface treatment options, including brushed finish, mirror finish, and sandblasting. - Electroformed nameplates: Precision micromachining technology

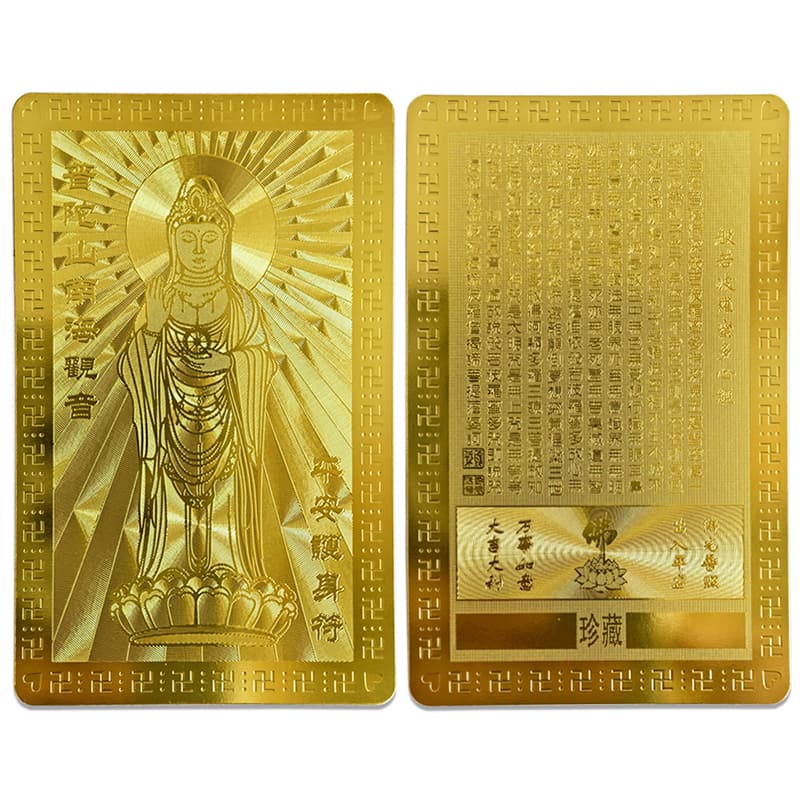

Electroformed nameplates utilize precision electrochemical molding technology, enabling the production of extremely fine patterns and text, with line precision reaching [a certain level].0.3mmIt achieves a level of precision unattainable by traditional processing techniques. It is widely used in high-end electronic product panels, precision markings on industrial equipment, button markings on home appliances, and corporate brand image displays, gaining high recognition from customers. - Etched panel: Chemical precision machining process

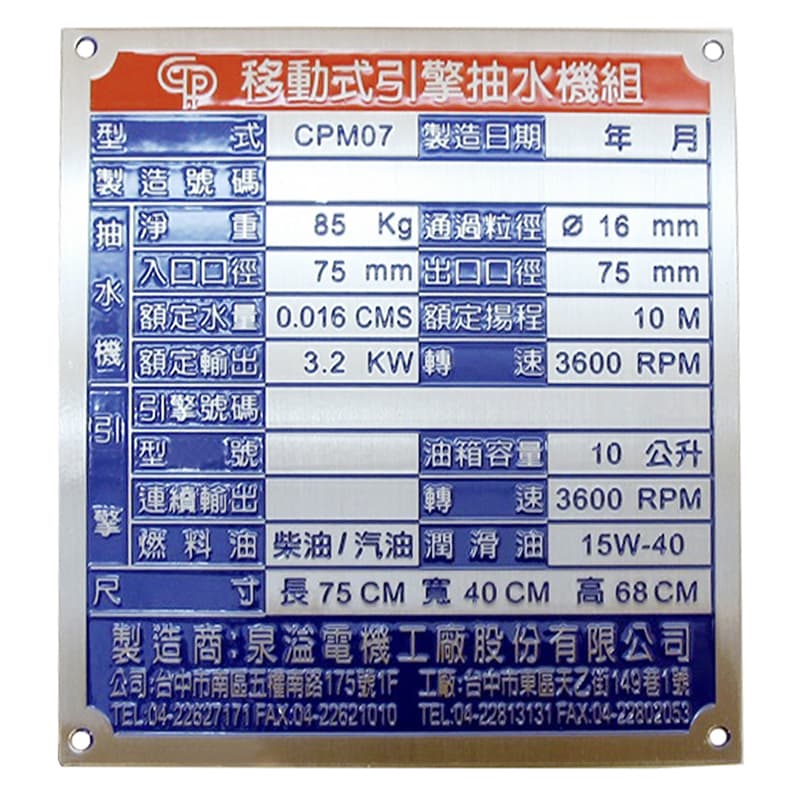

Etched panels utilize chemical etching technology, employing a precise photomask process and chemical reaction to create accurate patterns and text on metal surfaces. This technology is particularly suitable for mass production and offers excellent cost-effectiveness. Main applications include: instrument panel fabrication, machine operating interfaces, industrial equipment markings, badge production, and precision nameplates. Our etching panel services cover a variety of metals, including stainless steel, copper, and aluminum. - Die-cast signs: An artistic presentation of three-dimensional design

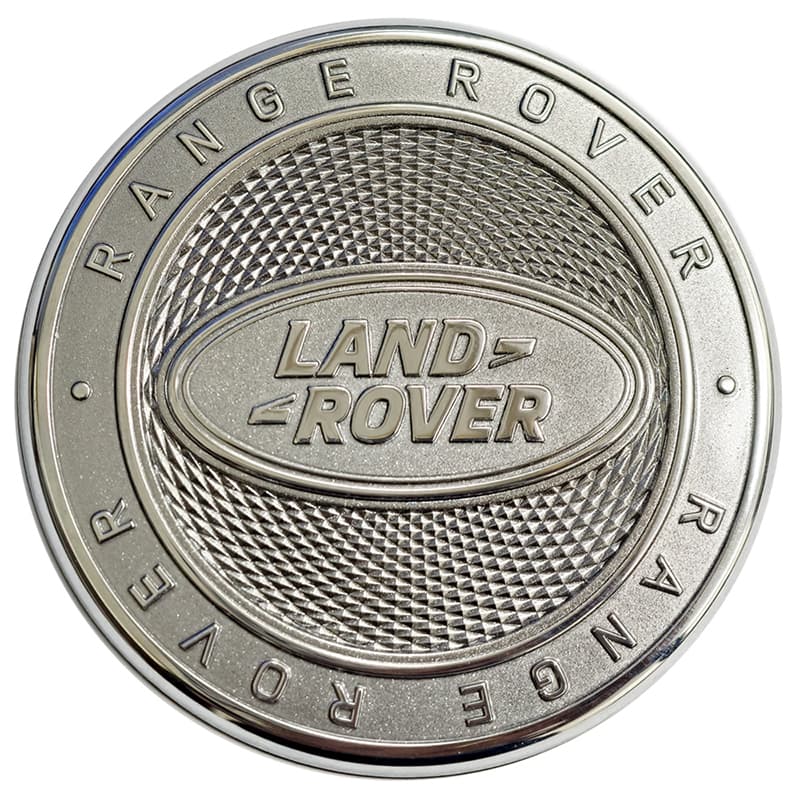

Die-cast signs utilize precision die-casting technology to create sign products with a three-dimensional effect. This technology is particularly suitable for applications requiring a three-dimensional effect, such as company logos, car badges, and machinery markings.

FKX 's metal processing services are ISO 9001 certified. No matter what kind of metal nameplate manufacturing service you need, FKX can provide the most professional technical support and quality assurance, adding professional value and brand image to your products.