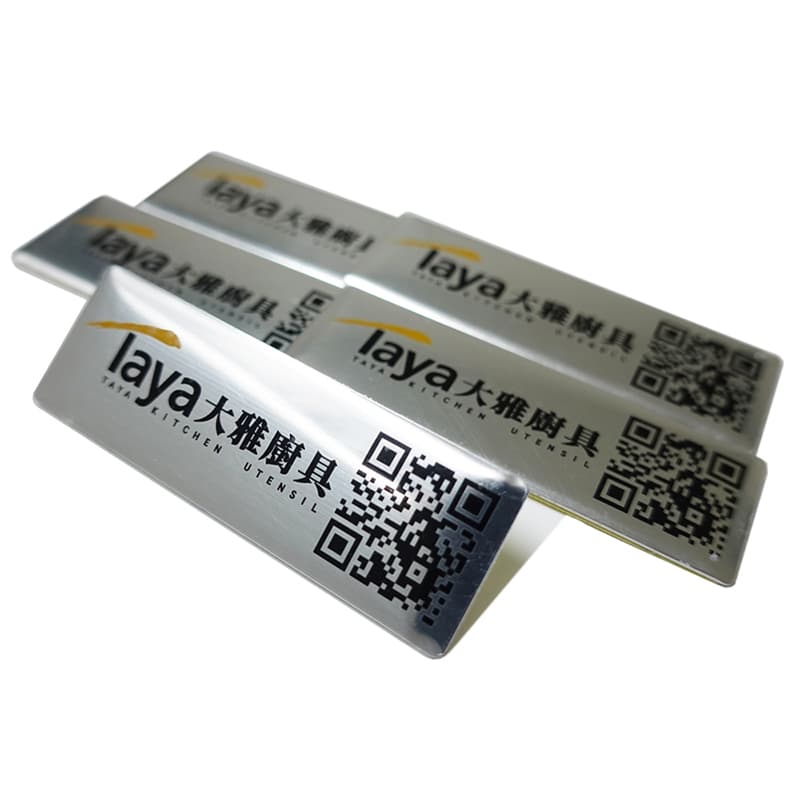

Metal nameplates for kitchen utensils with QR codes can also be used as employee identification badges in various industries for easy scanning and contact.

FKX specializes in the deep processing of high-quality metal materials such as stainless steel and aluminum alloys in the field of metal nameplate manufacturing. Stainless steel nameplates, made from SUS304 grade material, possess excellent corrosion resistance, high-temperature resistance, and mechanical strength, making them ideal for marine environments, chemical plants, and high-temperature equipment. Surface finishing processes include laser cutting, precision stamping, sandblasting, mirror finishing, and brushing, combined with professional screen printing or silkscreen printing technology to achieve clear lettering and long-lasting colors. Aluminum nameplates undergo anodizing to enhance surface hardness and wear resistance, are lightweight, and have excellent thermal conductivity, making them popular with the electronics, 3C, and precision instrument industries. FKX rigorous quality control ensures that metal nameplates not only have an aesthetically pleasing appearance but also superior durability, meeting the diverse marking needs of industrial clients.