Medical instrument panel and labeling: FKX precision printing, ensuring safety, accuracy, and cleanliness.

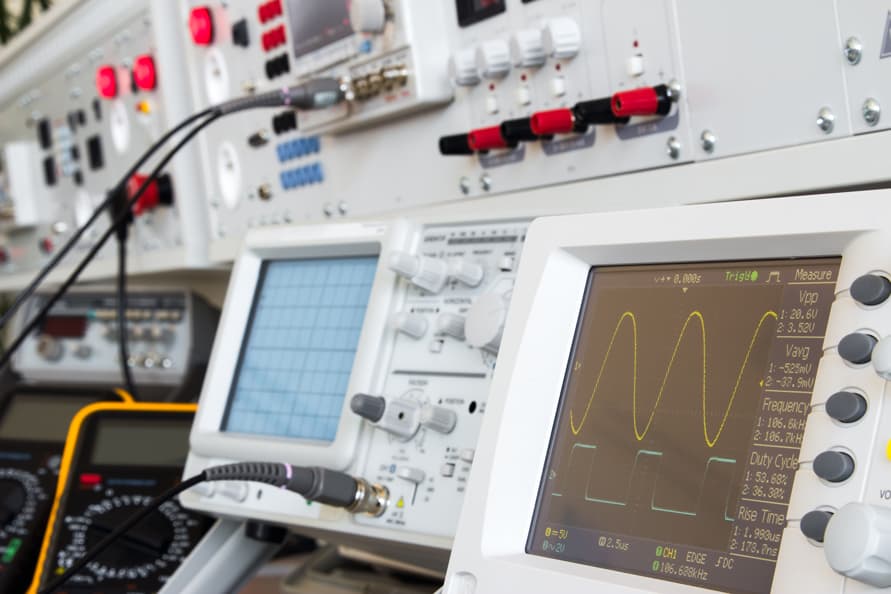

Medical instruments and equipment are vital tools for safeguarding life and health. The clarity of their interfaces and labelling, as well as hygiene standards, directly impact the accuracy of diagnosis, the safety of treatment, and the efficiency of healthcare workers. In the medical environment, characterized by frequent disinfection and cleaning, panels must be antibacterial, chemically resistant, and easy to clean, while equipment labelling must be clear, permanent, and compliant with regulations. FKX , with its rigorous quality management and precision printing technology, serves as your professional partner for printing plants in Taichung, providing customized panels and medical-grade nameplate solutions that meet international standards for medical instruments and equipment.

Core Solution

Antibacterial and easy-to-clean instrument panel

For medical device panel printing, cleanliness and durability are paramount. FKX specializes in PC panel printing technology, printing graphics and colors onto the inner layer of PC or PET films, resulting in a smooth, even surface that can withstand multiple daily wipes with alcohol or disinfectant without damage. For touchscreens, we can create protective instrument panels that combine high light transmittance and scratch resistance, integrating antibacterial coating materials to effectively inhibit bacterial growth and meet the high hygiene standards of medical institutions.

High-sealing membrane keypad

Traditional buttons have gaps that become breeding grounds for bacteria and dirt. Our membrane buttons (membrane panels) feature a one-piece, flat design that completely seals button functions, icons, and electronic circuitry within the membrane, achieving an IP65 or higher dust and water resistance standard. This allows for quick and thorough cleaning and disinfection of device surfaces, eliminating the risk of cross-infection. The flat design is also suitable for printing on various control panels, making it an ideal choice for modern medical equipment.

Precision and durable equipment nameplates and markings

From large computed tomography scanners to small physiological monitors, clear metal nameplates are crucial for device traceability (UDI) and asset management. FKX manufactures medical-grade stainless steel and aluminum nameplates, using precision metal etching processes to ensure clear and durable information such as device model numbers, serial numbers, and certification marks. For branding requiring a sophisticated look, our electroforming nameplate technology creates three-dimensional, high-gloss metal logos, enhancing the professional image of the equipment. We also offer a variety of customized stickers for labeling pipelines, functional areas, or warning messages.

FKX boasts an ISO-compliant production process, rigorously controlling every step from material selection, panel prototyping, sample confirmation to mass production and delivery to ensure product quality meets medical-grade requirements. We are not only a manufacturer but also your R&D strategy partner, providing professional design consultation and technical support to help your medical instruments stand out in the global market. Choose FKX , and together we will safeguard human health with precise and clean processes.