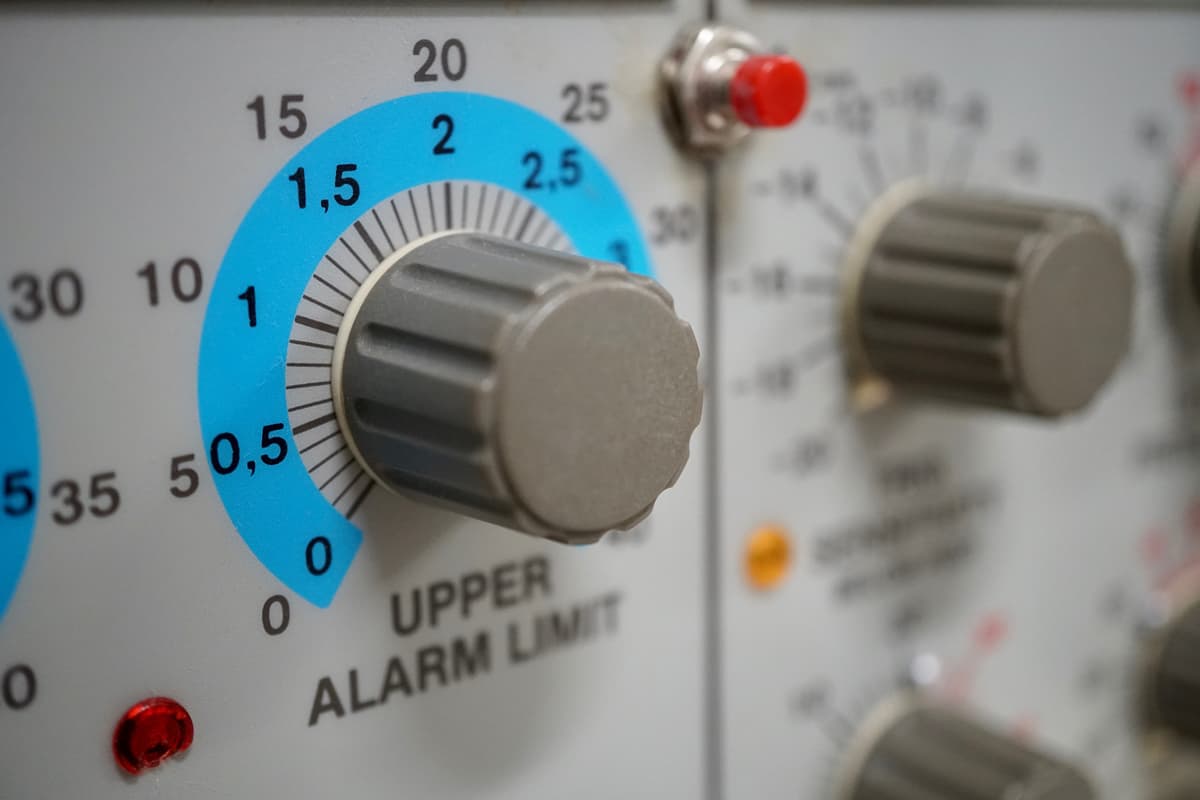

Upgraded operating room physiological monitoring equipment panel at medical center: Hygiene, safety, and operational precision all in one go.

A medical center is building a new operating room and needs to install advanced physiological monitoring equipment, which places extremely high demands on the hygiene and safety, touch accuracy, and regulatory compliance of the medical device panels. Existing samples have shown problems such as printing fading, insufficient anti-reflective properties, and unstable touch sensitivity after frequent alcohol disinfection, which may affect clinical interpretation and operational efficiency.

FKX proposed physiological monitoring device panel solution:

- Using medical-grade PC substrate as the core, it adopts an ink system and multi-layer structure design that has passed USP Class VI evaluation, with key graphics printed in-print for protection, and the outer layer is treated with hardening and UV resistance to ensure that it will not fade after long-term wiping.

- The panel is IP65 waterproof and dustproof, preventing cleaning fluids, sprays and dust from penetrating; the surface is coated with an anti-reflective coating and an anti-glare matte finish, maintaining high contrast and clear readability even under strong surgical light.

- The touch area features optimized stacking tolerances and a transparent window, improving touch sensitivity and positioning accuracy. ESD (Electrostatic Dissipation) treatment is also implemented to protect delicate electronic components.

- To meet infection control requirements, a seamless structure and rounded corners are adopted to reduce the risk of contaminant accumulation; the adhesive and bonding solution are matched with the medical device housing material to enhance long-term adhesion.

The project used digital printing for rapid prototyping to confirm visual hierarchy, button illustrations, and light transmission uniformity. During mass production, color difference and size SPC controls were established, and material and test documents were provided to facilitate regulatory and hospital acceptance. Six months after actual operation, medical staff reported smooth operation and a decrease in accidental touches. Due to its stable chemical resistance and scratch resistance, cleaning and maintenance time was reduced by about 40%, and the panel showed no yellowing or fading, which was highly praised by the equipment department.

If you are evaluating your needs for "medical device panels", "PC panel printing", "anti-reflective medical panels", etc., FKX can provide a complete solution from material selection and layout optimization to prototyping and mass production, helping operating rooms and clinical settings to balance hygiene, safety and operational efficiency.